What is a Chef Hat Called?

An iconic symbol in the food world is the chef’s hat. This headpiece has become synonymous with cooking with its

An iconic symbol in the food world is the chef’s hat. This headpiece has become synonymous with cooking with its

Ensuring your venue stays legally compliant. If your catering or hospitality venue is situated in England or Wales, your signage

Available in a range of sizes, our brand new illuminated menu covers are all the rage. Our illuminated LED menu

Shop across our entire range of catering & hospitality products with up to 70% off until midnight Monday 1st December.

Beer and pint glasses are an essential part of the drinking experience, designed to showcase the unique qualities of different beers and enhance the overall enjoyment of the drink. While these glasses may seem simple on the surface, they are actually the result of a complex manufacturing process that involves a range of materials and techniques.

In this article, we will explore the process of how beer glasses and pint glasses are made, from the raw materials to the finished product.

The raw materials used in the production of beer glasses and pint glasses are typically glass, crystal, or plastic. Glass and crystal are the most common materials used for high-quality beer glasses, as they are durable, easy to clean, and can enhance the flavour and aroma of the beer. Plastic is also used for beer glasses, particularly for outdoor events or other situations where durability is a priority.

The glass used in the production of beer glasses and pint glasses is typically made from a mixture of sand, soda ash, and limestone, which are melted together at high temperatures to form molten glass. The quality of the glass depends on the purity of the raw materials used and the precision of the manufacturing process.

The manufacturing process of beer glasses and pint glasses involves a range of techniques, including blowing, pressing, and cutting.

Blowing is the most common technique used in the production of beer glasses and pint glasses. The process involves heating a small amount of molten glass and then blowing air into the glass to create a bubble. The glass is then shaped and moulded using a range of tools and techniques to create the final shape of the glass. This process is typically used for handcrafted, artisanal beer glasses and pint glasses, which can have unique and intricate designs.

Pressing is a mass-production technique used to create beer glasses and pint glasses in large quantities. The process involves pouring molten glass into a mould, which is then pressed using a machine to create the final shape of the glass. This process is typically used for simple, straightforward designs that can be produced quickly and efficiently.

Cutting is a technique used to add decorative elements to beer glasses and pint glasses, such as patterns or designs. The process involves using a diamond-tipped tool to etch or engrave the surface of the glass, creating a textured or three-dimensional effect. This technique is typically used for high-end, luxury beer glasses and pint glasses.

Once the beer glasses and pint glasses have been shaped and moulded, they undergo a range of finishing techniques to ensure that they are smooth, polished, and free from defects. This can include grinding, polishing, and sandblasting to remove any rough edges or imperfections in the glass.

Quality control is an essential part of the manufacturing process for beer glasses and pint glasses. Once the glasses have been finished, they undergo a range of tests to ensure that they meet strict quality standards for durability, clarity, and overall performance. This can include tests for strength, resistance to temperature changes, and resistance to impact.

Beer glasses and pint glasses are an essential part of the drinking experience, designed to showcase the unique qualities of different beers and enhance the overall enjoyment of the drink. The manufacturing process for these glasses involves a range of materials and techniques, including blowing, pressing, cutting, and finishing, as well as strict quality control standards to ensure that the glasses are durable, high-quality, and free from defects.

In the United Kingdom, beer glasses come in a range of sizes and shapes, each designed to enhance the drinking experience of different types of beers. Here are some of the most common sizes of beer glasses used in the UK:

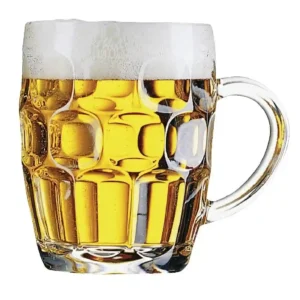

The pint glass is the most common size of beer glass used in the UK, and is typically used for serving ales, lagers, and other types of beer. The glass has a capacity of 20 fluid ounces or 568 millilitres and is tall, with a slight taper towards the top. This design allows for the beer to be poured with a thick, foamy head, which can enhance the aroma and flavour of the beer.

The half pint glass is a smaller version of the pint glass, and is typically used for serving smaller portions of beer. The glass has a capacity of 10 fluid ounces or 284 millilitres and is similar in shape to the pint glass, with a slight taper towards the top. This size is often preferred by those who want to enjoy a beer without consuming a full pint.

The schooner glass is a smaller version of the pint glass, and is typically used for serving stronger, more flavourful beers such as IPAs and stouts. The glass has a capacity of 13 fluid ounces or 369 millilitres and is shorter and wider than the pint glass, with a thick, sturdy base. This design allows for the beer to be swirled and aerated, which can enhance the aroma and flavour of the beer.

The tankard is a traditional type of beer glass that is often used in pubs and bars in the UK. The glass has a capacity of around 20 fluid ounces or 568 millilitres and is typically made of pewter, ceramic, or glass. This design features a sturdy handle, which makes it easier to hold and carry, and is often used for serving ales and other types of beer.

The size and shape of beer glasses can have a significant impact on the overall drinking experience, enhancing the aroma, flavour, and appearance of different types of beers. From the classic pint glass to the sturdy tankard, the UK has a wide range of beer glasses to suit every taste and preference. So next time you order a pint of your favourite beer in the UK, take a moment to appreciate the unique qualities of the glass and the role it plays in enhancing the overall drinking experience.

A Company Registered in England & Wales Company Registration Number: GB05069286 VAT Registration Number: GB867112521 Smart Hospitality Supplies is a trading division of The Smart Marketing & Media Group Limited